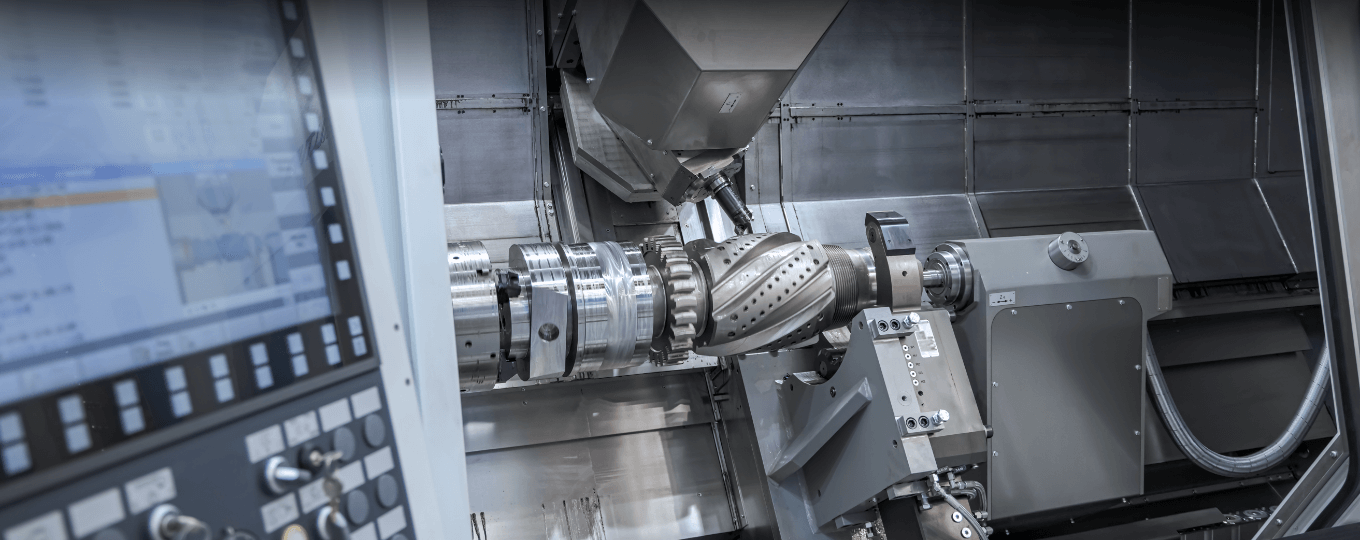

Remote Monitoring Solution for Injection Molding Machines

Featuring strong data transmission and edge computing capabilities, the IG502 offers a remote monitoring solution for distributed machines and enhances efficiency for facility operation and maintenance.

Background

Injection molding machines play a crucial role in manufacturing, producing diverse plastic products. Yet, conventional monitoring methods encounter problems such as process opacity, limited manual inspections, and delayed equipment fault detection.

To tackle these issues, a remote monitoring solution for injection molding machines emerges. By leveraging IoT, remote monitoring, and cloud platform technologies, this solution empowers real-time monitoring, data collection, and remote operations for these machines.

Customer Requirements

Real-time Monitoring and Remote Control

Enable real-time monitoring of injection molding machine’s key parameters, such as temperature, pressure, and speed, through a cloud platform or local server. Allow remote control to adjust parameters and optimize the production process.

Fault Diagnosis and Predictive Maintenance

An intelligent system is needed to analyze collected data and diagnose potential machine faults, issuing timely alerts to prevent production interruptions and equipment damage. Predictive maintenance can be employed to create maintenance plans based on equipment status, reducing unplanned downtime.

Data Analysis and Reports

An advanced data analysis platform is necessary to process, analyze, and visualize the machine’s operating data. It should support report and chart generation, enabling clients to monitor production efficiency, quality metrics, equipment utilization, and drive continuous improvement.

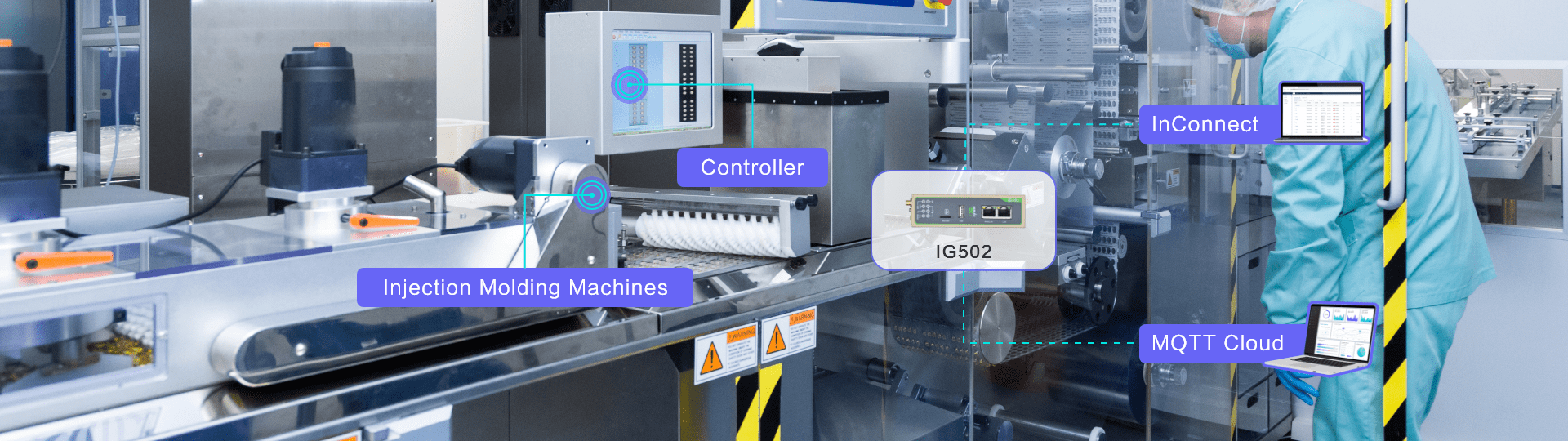

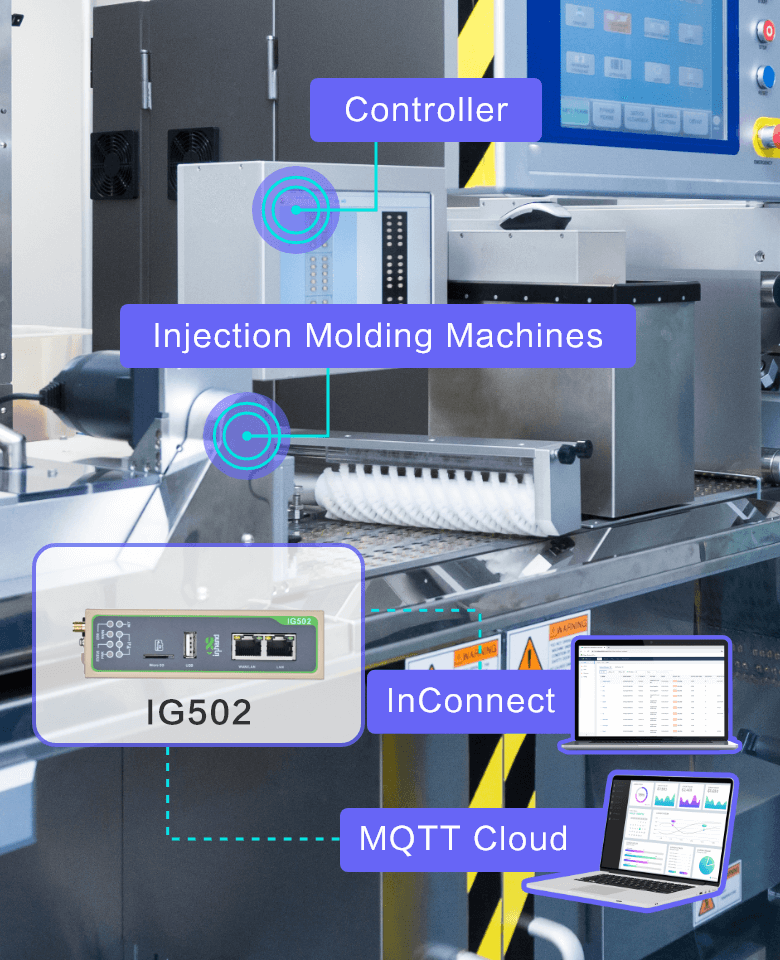

Solution

The solution includes air compressors, InGateway502 (IG502) edge computing gateways, remote management platform, etc. The IG502 connects to the air compressor controller, collects key on-site data such as oil temperature and lubricant in real-time, and after local data filtering and preprocessing, transmits the data to the remote management platform through dedicated protocols via the 4G network of the mobile operator for further analysis and processing. Customers can view, analyze, and statisticize the data anytime through computer or mobile terminals.

Maintenance personnel can establish a maintenance channel with the on-site air compressor through the client, and remotely configure, debug, and upgrade the air compressor to achieve remote maintenance and remote online monitoring functions, and real-time grasp the operating status of the on-site air compressor to improve the operational efficiency of the air compressor. By timely detecting and resolving problems through preventive maintenance, downtime can be reduced, and the service life of the equipment can be maximized.

Capabilities

Supports Mainstream Industrial Protocols and Clouds for Easy Remote Monitoring and Reduced Costs

The IG502 supports Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA Client, and other major industrial protocols, making it easy to send device data to the cloud for remote monitoring and preventive maintenance, reducing operational costs and improving customer satisfaction.

Python Programmable, Built for Developers

The IG502 comes with an embedded secondary development platform that supports Python programming, enabling customers to effortlessly implement specific business logic and achieve personalized functions or services.

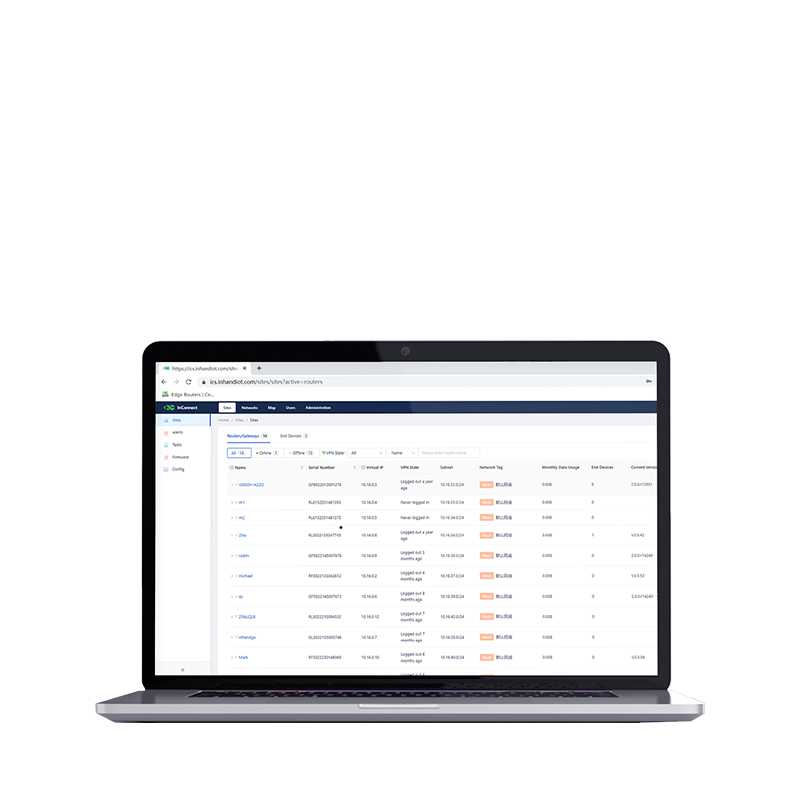

Easy Management for Large-scale Deployment

The IG502 supports web interface configuration and enables easy setup. InHand’s Device Manager can efficiently centralize the management of numerous devices, allowing users to monitor gateway status anytime anywhere.

Stable and Reliable Network Keeps Devices Always Online

- The IG502 ensures excellent and stable network service for unmanned IoT sites, guaranteeing uninterrupted connectivity and device reliability.

Dual SIM, automatic switch to high-quality carrier’s network; - Multiple-level link detection mechanism for link status monitoring, automatic redial and self-recovery from faults;

- Embedded watchdog technology ensures normal operation.

Powerful Edge Computing Capabilities Enable Intelligent Data Processing

The IG502 is equipped with a powerful ARM Cortex-A8 processor, running at 600MHz with 512MB RAM and 8GB eMMC. This robust edge computing capability enables intelligent data processing, optimization, real-time response, and smart analytics for on-site devices.

Products

More Applications

Featuring powerful edge computing capabilities, support for multiple industrial protocols and IoT clouds, industrial design, the IG502 delivers a reliable remote monitoring solution for air compressors.

Real-time visualization, predictive maintenance, and data-driven decision-making for streamlined operations. High-speed connectivity, industrial protocol compatibility, and Docker support ensure seamless deployment and efficient management.

Increasing machines and on-site devices connected to the Internet creates a great challenge for data collection and processing. Equipped with powerful edge computing capabilities, the InGateway902 excellently relieves the pressure of massive data and enhances productivity.

-Bessie⾃⼰写了.png)

格创东智-EN-✅.png)