Telematics for Cold Chain Logistics

Integrating extensive interfaces, multiple diagnostic protocols and major IoT clouds, the VT310 delivers reliable vehicle telematics for col chain logistics, while remaining budget friendly.

Background

As the world’s leading manufacturer of air compressors, a company has been committed to improving product quality and user experience through innovative technologies and services. They hope to connect the machine to the network, so that the maintenance staff can check and understand the operation status of the air compressor at any time, discover anomalies in time, and deal with them in a precautionary manner, so as to reduce the loss caused by failure and stop, and provide better service and value for customers.

Customer Requirements

Improve Cargo Quality and Safety

The ability of real-time monitoring and tracking of temperature, humidity, and location ensures optimal conditions for goods throughout the logistics process. This reduces the risk of damage and waste, enhancing cargo quality and safety.

Reduce Operational Costs

Prompt alerts for anomalies enable proactive measures to prevent temperature deviations, thus reducing spoilage and returns. This saves costs and improves profitability.

Improve Supply Chain Visibility and Transparency

The ability of real-time monitoring, alerts, and reports for temperature and humidity provides critical data and insights throughout the logistics process. This enables informed decision-making and optimization of supply chain management.

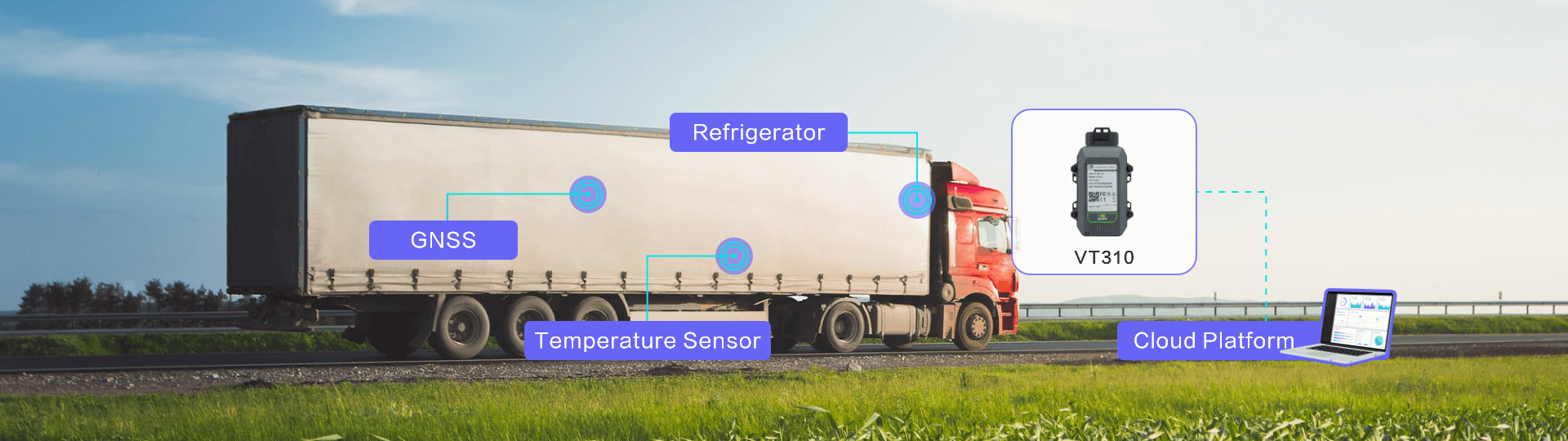

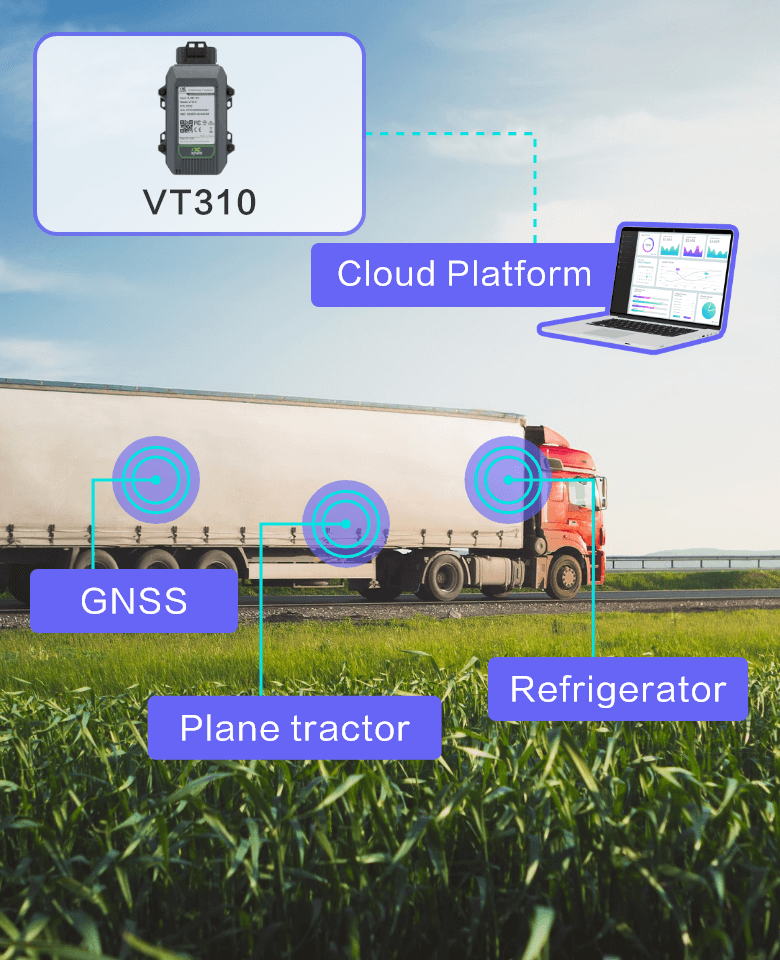

Solution

The intelligent cold chain logistics solution enables real-time data collection and monitoring of refrigeration equipment. It uploads location, temperature, operation status, fuel consumption, etc. to the cloud, and sends alerts for anomalies, allowing prompt troubleshooting and thus a safe storage environment for goods.

The solution comprises the refrigeration system, the VT310 telematics gateway, refrigeration unit generator set, and cloud platform. The VT310 connects to various sensors (temperature, humidity, fuel level, door magnetic) via RS485 and the refrigeration system controller via RS232. It enables control commands for the refrigeration unit, provides real-time GPS location, and features automatic sleep mode when the device is stationary and the refrigeration unit is inactive, with wake-up capability. This versatile solution accommodates both train and road transportation scenarios.

Benefits

Reliable and Stable Operation in Harsh Environments

Designed with full industrial grade, the VT310 can withstand frequent current and voltage fluctuations, intense vibrations, and extreme temperatures. With IP67 protection rating, it is resistant to dust and water splashes.

Reliable Cellular Network Connectivity, Always Online

With continuous LTE CAT4 network access and multi-layer link detection and recovery, the VT310 ensures 24/7 connectivity across buses.

Uninterrupted High-precision Vehicle Positioning

Equipped with highly sensitive GNSS that supports GPS, BeiDou, Galileo, and GLONASS, the VT310 offers precise positioning of refrigeration units.

Real-time Monitoring of Refrigeration Equipment

Integrated with RS232 and RS485, the VT310 can collect data from refrigeration unit controllers using the Modbus protocol, providing real-time information on their status.

Support for Major IoT Clouds

Compatible with multiple IoT clouds, such as AWS and Azure, and supports OTA upgrades.

Products

More Applications

The VG710 smart vehicle gateway enables real-time monitoring of ground service vehicles, shuttle buses, refueling vehicles, luggage vehicles, and aircraft trailers, etc, and also including various functions such as vehicle status monitoring, maintenance record, fault alarm, dispatching nearby vehicles.

The VG710 provides high-speed, secure and reliable 5G connectivity for firetrucks, enabling quick and reliable data transmission, vehicle tracking and management.

The VG710 provides high-speed, secure and reliable 5G connectivity for medical vehicles, enabling medical data transmission, vehicle tracking and management, driving behavior monitoring and access to remote diagnosis and consultation.

.png)

E.png)