Smart Secondary Water Supply Pump Rooms

The IG902 edge computing gateway connects onsite PLCs to the cloud, helps collect data from the site, process data locally and upload them to the cloud, ensuring clean, high-quality drinking water for urban residents.

Background

A local government office issued a plan for construction of secondary water supply facilities, which aims at further strengthening the safety of the “last mile” water supply, improving the end of the water quality, improving the public’s sense of security and well-being of water. In order to respond to the government’s call to realize the unified construction and management of secondary water supply, to ensure that water pressure, water quality and other indicators meet the government’s requirements, and to ensure the safety of water supply, a local water group hopes to improve the quality of water supply and user experience through innovative technologies and services. Specifically, it wants to monitor the operation status of equipment 24 hours a day, grasp the water quality data in real time, timely detection of equipment abnormalities and water quality problems, to ensure the safety of water supply and provide residents with quality and reliable water supply services.

Customer Requirements

Real-time Monitoring, Complete Control of Various Data

Achieve remote monitoring and management of multiple pump rooms distributed across communities, enable real-time observation of operational status and water quality, increasing management efficiency, thus ensuring high-quality water supply services for residents.

Prompt Alerts, Permanent Water Quality Assurance

Online warning services enable maintenance staff to promptly detect water quality anomalies, thereby preventing contamination or deterioration of water quality and effectively safeguarding water quality.

Intelligent Analysis for Better Sustainability

Achieve intelligent diagnosis of the water supply system’s operational status through in-depth data exploration and analysis. This helps improve decision-making, reducing resource waste, and facilitates optimization of the water supply system.

Solution

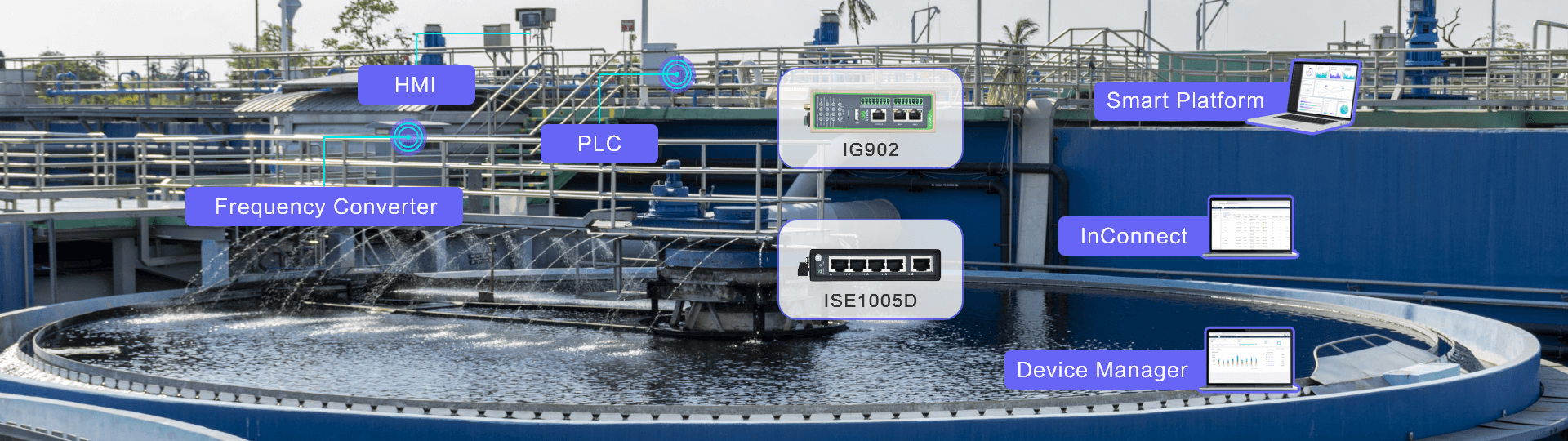

InHand’s solution consists of PLCs, inverter, HMI, video monitoring system, InHand switch ISE1005D, the IG902 edge computing gateway, and remote platform for secondary water supply.

PLCs, HMIs, cameras, etc. in the pump room are connected to the Ethernet port of the IG902 via ISE1005D. The IG902 collects thousands of equipment operation variables, including pH levels, turbidity, pump operating time, etc. at intervals of seconds.

Collected data is processed at the edge for calculations and water quality alarms. Processed data is sent to the cloud (enterprises can build their platforms based on AWS, Azure or private clouds) in the required format via 4G or wired networks. The cloud platform allows remote monitoring of pump rooms and responds to control commands. Maintenance staff can use a mobile app for real-time status updates. Malfunction data is sent to the dispatch center, enabling remote issue resolution through the cloud platform. The IG902 in different pump rooms can be remotely upgraded and configured using the Device Manager, and the InConnect VPN channel enables remote PLC debugging and updates.

Capabilities

High-speed, Secure, and Reliable Network Connectivity with Uninterrupted Device Operation

The IG902 is available with LTE, Wi-Fi, and wired connections. It incorporates multiple link redundancy technologies to ensure a consistently high-speed and reliable network connection. This guarantees uninterrupted device operation within a continuous network transmission environment.

Supports Mainstream Industrial Protocols and Clouds for Easy Remote Monitoring and Reduced Costs

The IG902 supports major PLC protocols such as those of Siemens, Mitsubishi, Omron, etc. making it easy to send device data to the cloud for remote monitoring and preventive maintenance, reducing operational costs and improving customer satisfaction.

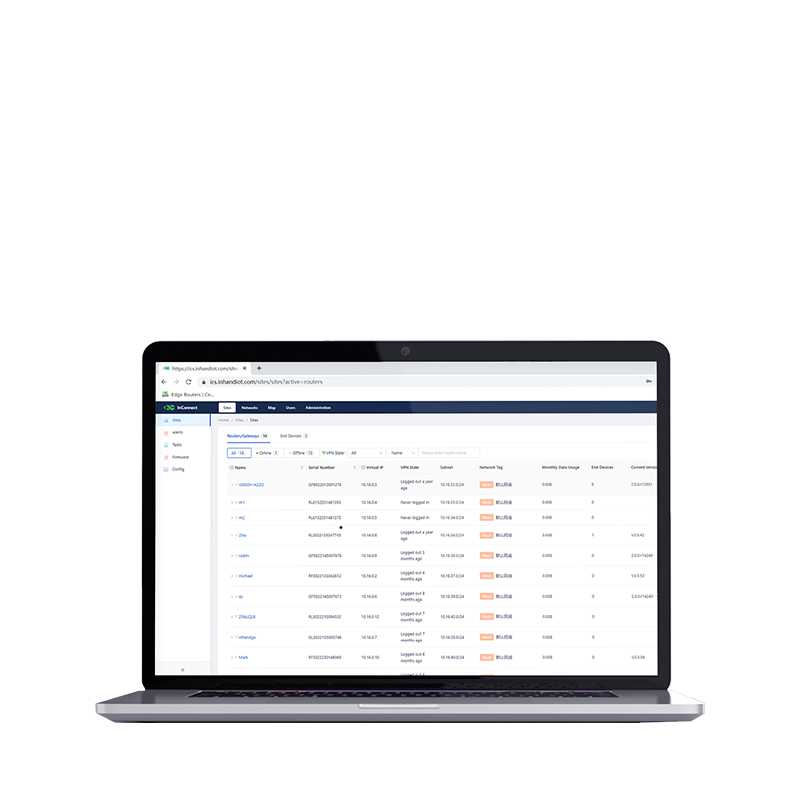

Remote Maintenance of Customer Devices with the InConnect

The IG902 supports the InConnect remote access service, providing a VPN remote maintenance channel for updating and debugging PLC programs and swiftly responding to device malfunctions.

Easy Management for Large-scale Deployment

With web-based configuration, the IG902 is user-friendly. The Device Manager efficiently centralizes the management of numerous devices, allowing real-time monitoring of gateway operational status from anywhere.

Products

More Applications

To better monitor the status of bearings and conduct preventive maintenance, InHand Networks delivers a solution featuring the IG902 edge computing gateway, helping acquire real-time data of the bearing status, upload data to the cloud for analysis and maintenance.

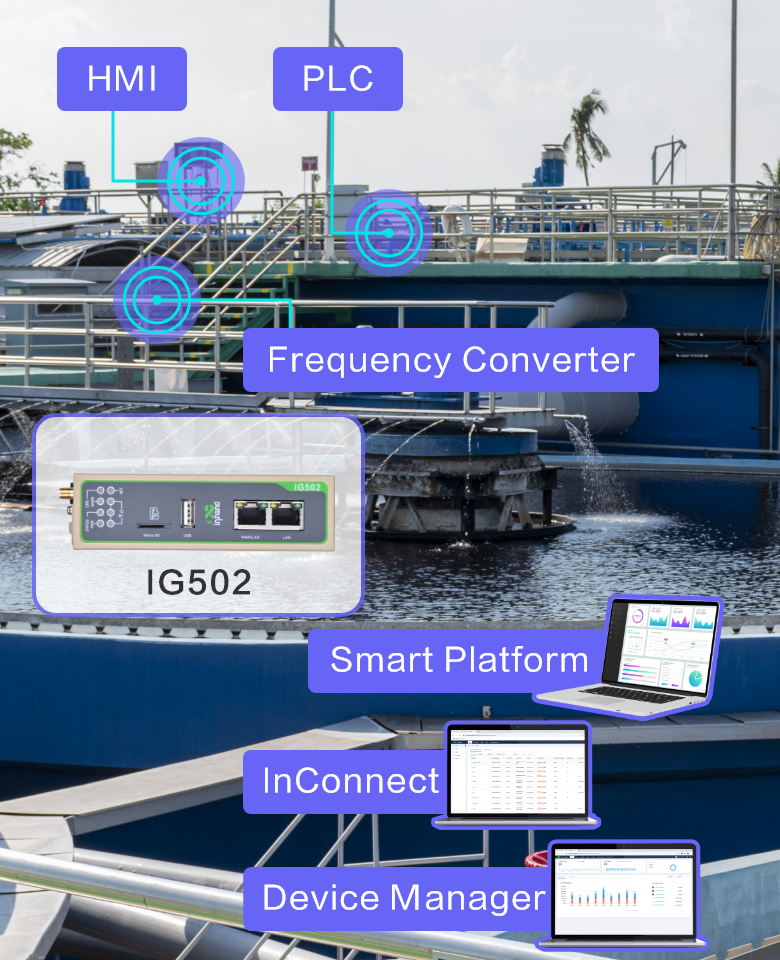

The “cloud + end” remote monitoring solution featuring the IG502 and the InConnect delivers real-time communications and efficient monitoring & control.

The IG902 enables users to oversee the operation status of the heat supply system, acquire accurate and effective data, thus ensuring secure and stable operation of the devices.

(中国)EN.png)