Remote Monitoring Solution for Digital Factory

Today’s digital factory features real-time visualization, predictive maintenance, and data-driven decision-making for streamlined operations. Our solutions equipped with high-speed connectivity, industrial protocol compatibility, and Docker support ensure seamless deployment and efficient management.

Background

In today’s rapidly evolving industrial landscape, the demand for enhancing production efficiency, reducing costs, and achieving intelligent operational management has never been more urgent. As a result, IoT-based smart digital factory remote monitoring solutions have taken center stage, capturing the attention of enterprises seeking innovative solutions for their needs.

Customer Requirements

Real-time Visualization and Remote Management

Monitor and manage factory equipment and production lines in real time. Users can access equipment status, production metrics, and critical performance indicators anytime, anywhere, enabling timely decision-making and adjustments.

Fault Warning and Predictive Maintenance

Provide fault warning capabilities to detect equipment malfunctions, anomalies, and potential issues early. Implement preventive maintenance measures to reduce downtime, lower repair costs, and achieve higher equipment reliability and productivity.

Data-driven Decision-making and Optimization

Record factory equipment operational data and offer data querying and export functionalities to support informed operational decisions. Optimize resource utilization and enable intelligent decision-making through accurate and timely data insights.

Solution

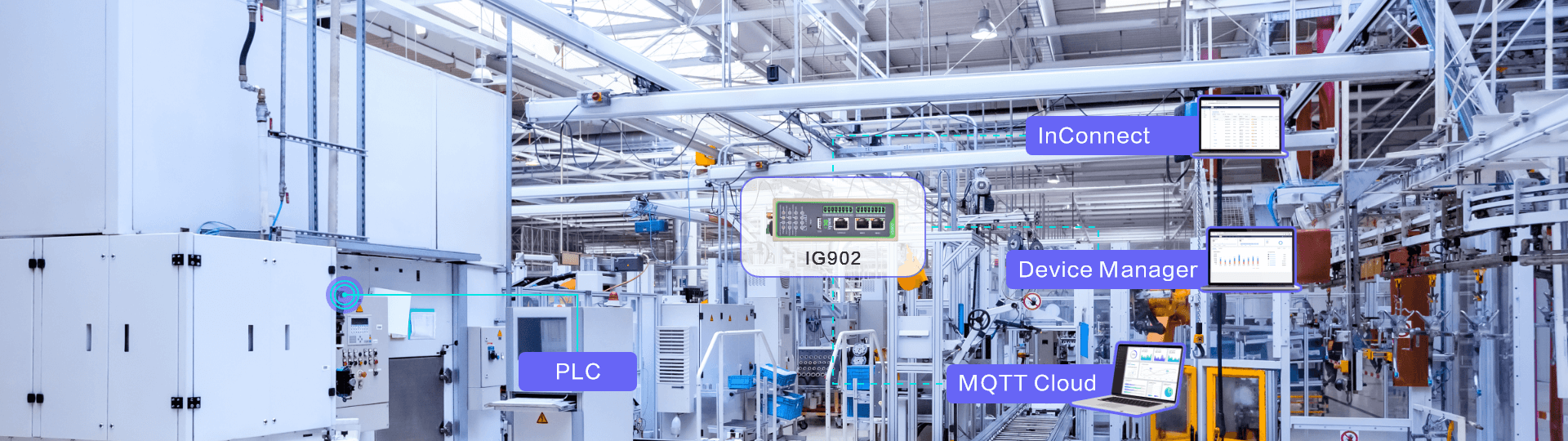

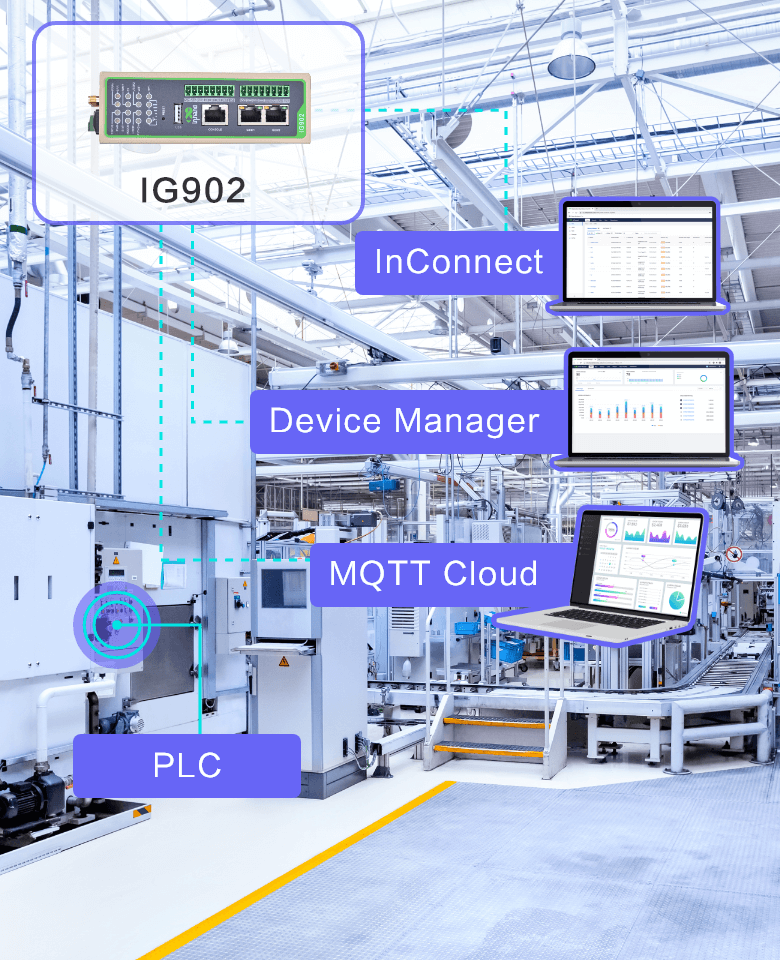

InHand’s remote monitoring solution for digital factory enables seamless IoT transformation, cost-effective maintenance, and heightened productivity.

The solution consists of field PLCs, the IG902 edge computing gateway, and the IoT cloud platform. The IG902 captures real-time data from the PLC, filters it, and transmits it over 4G networks with proprietary protocols to the remote management platform for analysis. Through the InConnect remote access service, maintenance staff can remotely configure, debug and upgrade onsite PLCs. The DeviceManager ensures unified management, remote maintenance and real-time monitoring of InHand’s devices, optimizing operational efficiency and extending equipment lifespan with proactive maintenance.

Capabilities

High-speed, Secure, and Reliable Network Connectivity, Devices Always Online

Available with LTE, Wi-Fi, and wired connections, along with various link redundancy technologies, the IG902 ensures continuous and reliable network transmission for uninterrupted device operation.

Compatible with Mainstream Industrial Protocols and Clouds for Easy Remote Monitoring and Reduced Costs

The IG902 supports Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA Client, and other major industrial protocols, making it easy to send device data to the cloud for remote monitoring and preventive maintenance, reducing operational costs and improving customer satisfaction.

Python Programmable, Built for Developers

The IG902 comes with an embedded secondary development platform that supports Python programming, enabling customers to effortlessly implement specific business logic and achieve personalized functions or services.

Efficient Development and Deployment with Docker

The IG902 supports Docker, providing customers with a flexible, portable, efficient, and scalable application deployment and management solution. It enhances development and operational efficiency while reducing system resource consumption and environment configuration complexity.

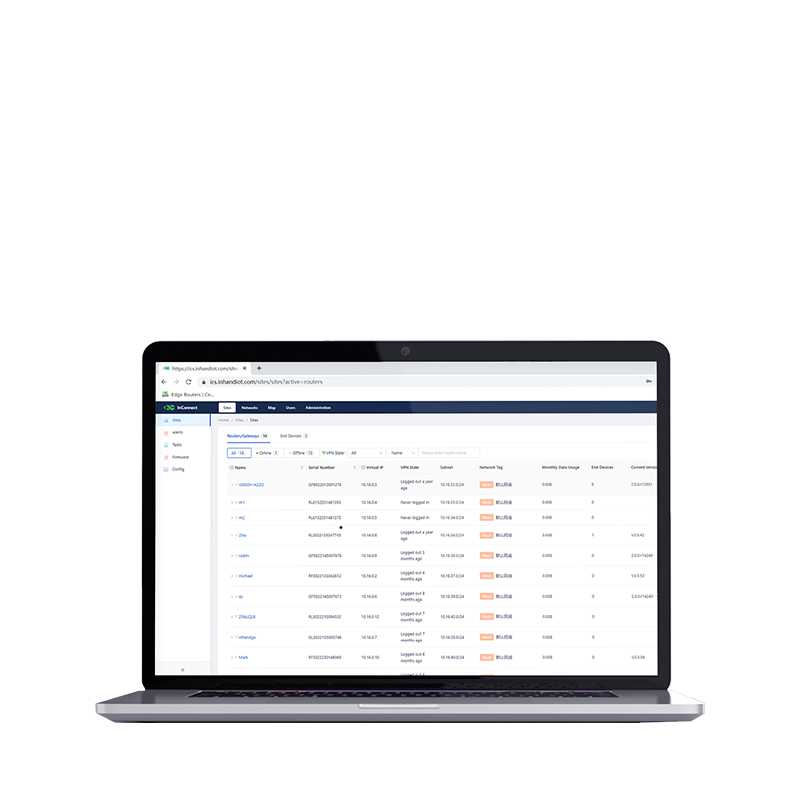

Remote Device Maintenance with InConnect

The IG902 supports the InConnect service, which offers remote maintenance VPN tunnels for updating, debugging PLC programs, or remotely modifying device parameters to respond quickly to equipment malfunctions.

Easy Management for Large-scale Deployment

The IG902 supports web interface configuration and enables easy setup. The Device Manager efficiently centralizes the management of numerous devices, allowing users to monitor gateway status anytime anywhere.

Products

More Applications

Featuring fast and reliable networking, python programming and industrial-grade design, the IG902 offers remote monitoring to the CNC machines, significantly saving both manual labor and costs.

Equipped with edge computing capabilities, the IG902 pre-processes, filters and cleans the constantly streaming data before sending them to the cloud, relieving the pressure of the data center and enhancing efficiency.

Increasing machines and on-site devices connected to the Internet creates a great challenge for data collection and processing. Equipped with powerful edge computing capabilities, the InGateway902 excellently relieves the pressure of massive data and enhances productivity.

EN-✅.png)